Throughout our company’s experience in building robots in America, we’ve identified several key advantages that come with overseeing our own manufacturing.

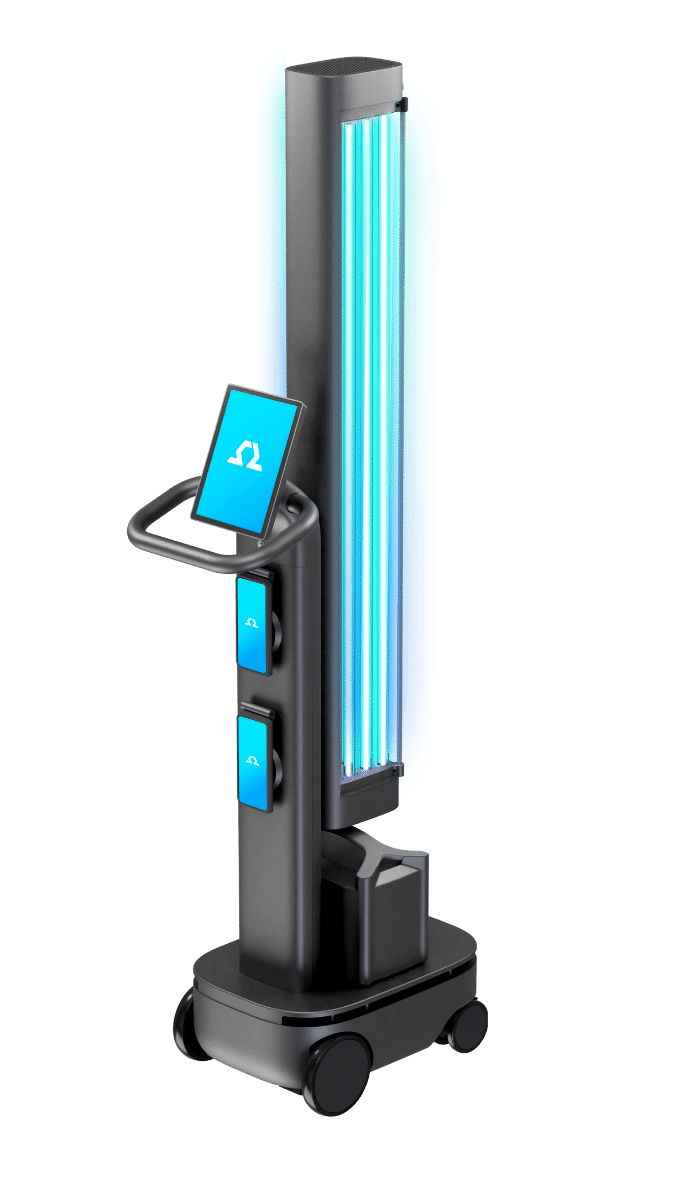

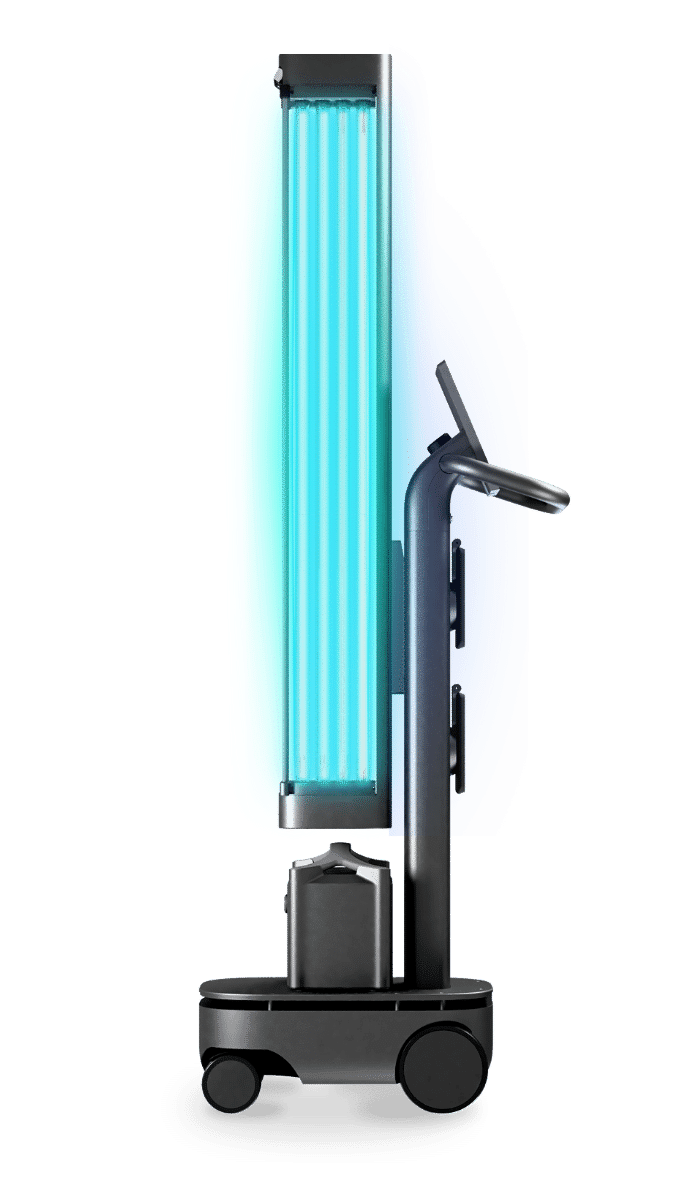

At OhmniLabs, we’re committed to ensuring that each product we produce is of the highest quality. With our design method deeply rooted in robotic expertise, we want the results to reflect that thoughtful & intentional process. But no matter how strong our plans and blueprints may be, if the manufacturing process is at all compromised or shortsighted, then the entire operation could be rendered useless. To better secure a finished product that equaled what we envisioned, we decided to bring the manufacturing directly into our headquarters in Silicon Valley, making all of our robots in America via additive manufacturing.

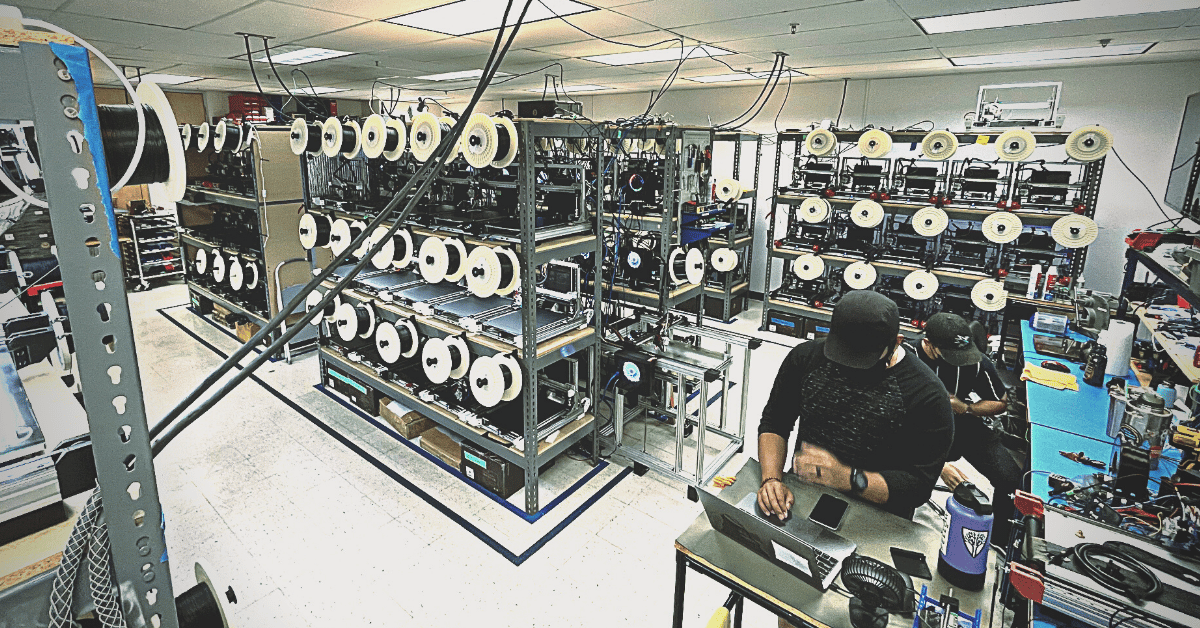

Historically speaking, 3D printing was mainly used for prototyping, with many believing it wasn’t a feasible choice for full-scale production. But by committing ourselves to the process, we proved the doubters wrong and now manufacture thousands of robots each year using our very own 3D printers.

Throughout our company’s experience in building robots in America, we’ve identified several key advantages that come with overseeing our own manufacturing.

Top 10 Benefits of Manufacturing Robots in America

- Supply Gap — We’re not subjected to potential shipping delays or disruptions in the supply chain, which reports indicate could remain unstable for the next decade, if not longer. In fact, during the pandemic, building in-house allowed us to triple production while other manufacturing shops had to completely shut down.

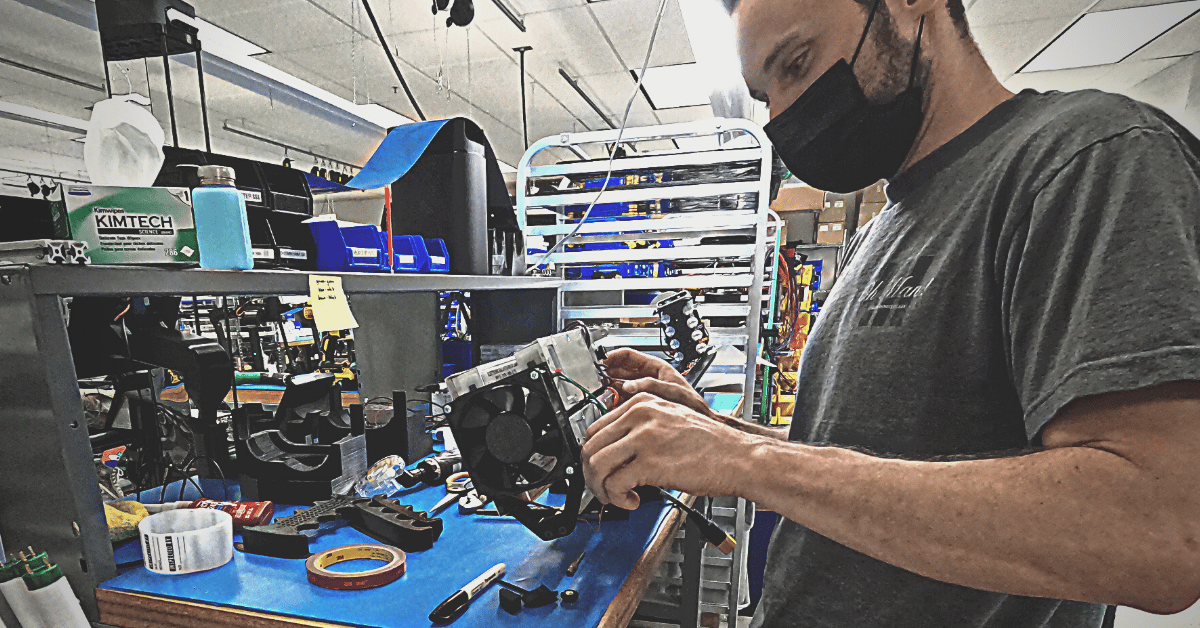

- Upfront Cost — We can create robots at a fraction of the cost of traditional manufacturing, which then turns into significant savings for our customers.

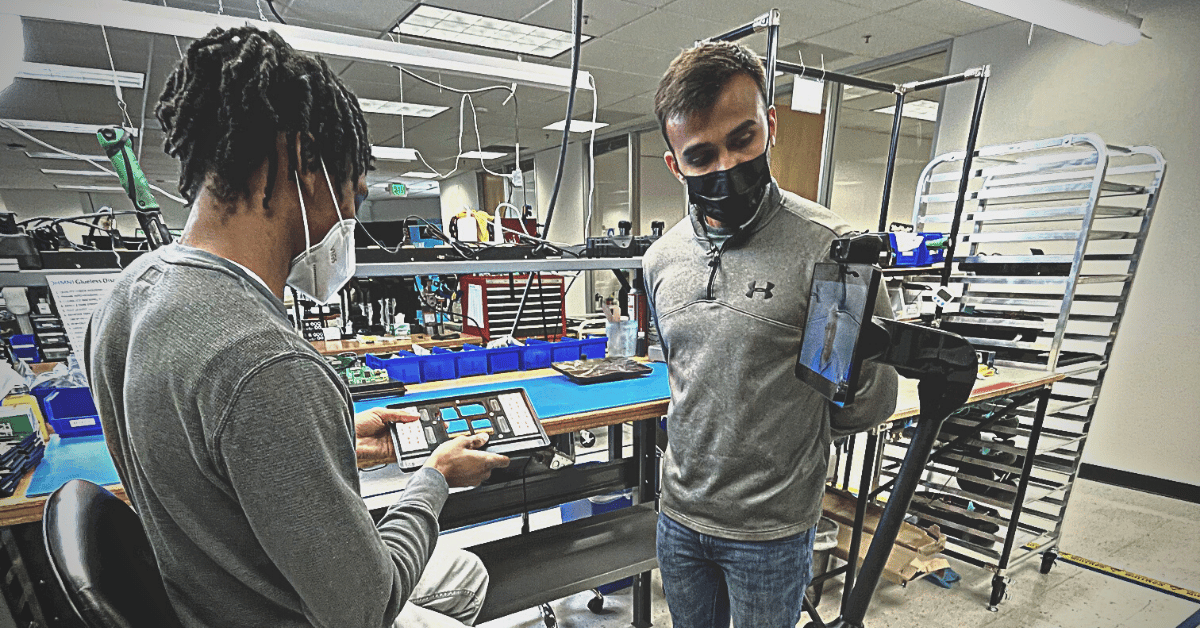

- Quality Control — Every piece of our product gets a first-hand, thorough quality check, ensuring that each part, from the smallest component to the completed robot, is defect-free.

- Rapid Iteration — We’re able to prototype and make changes on the fly, trying out new styles and ideas without going back and forth with a manufacturer.

- Small Spaces — Our 3D printers don’t require a lot of space, which allows us to maintain a smaller office. This was especially important in our nascent days, where using a larger location would’ve been a challenge.

- Scalability — As demand for our products increases, we can add more printers without any hassle, allowing us to keep up and continue providing our products with ease.

- On-Demand — When new orders come in, we’re able to start manufacturing the product right away and quickly get it into the hands of our customers.

- Inventory Control — In alliance with the above, we keep a limited supply of products in inventory, further allowing us to keep our office space manageable.

- Customization — Our customers can request different colors, logos, and other design tweaks that we can readily accommodate without communicating the info to a 3rd party.

- Holistic Process — We design and build our robots with an all-encompassing approach, seeing it through from start to finish with every stage influencing the others.

Conclusion — Building Robots at OhmniLabs

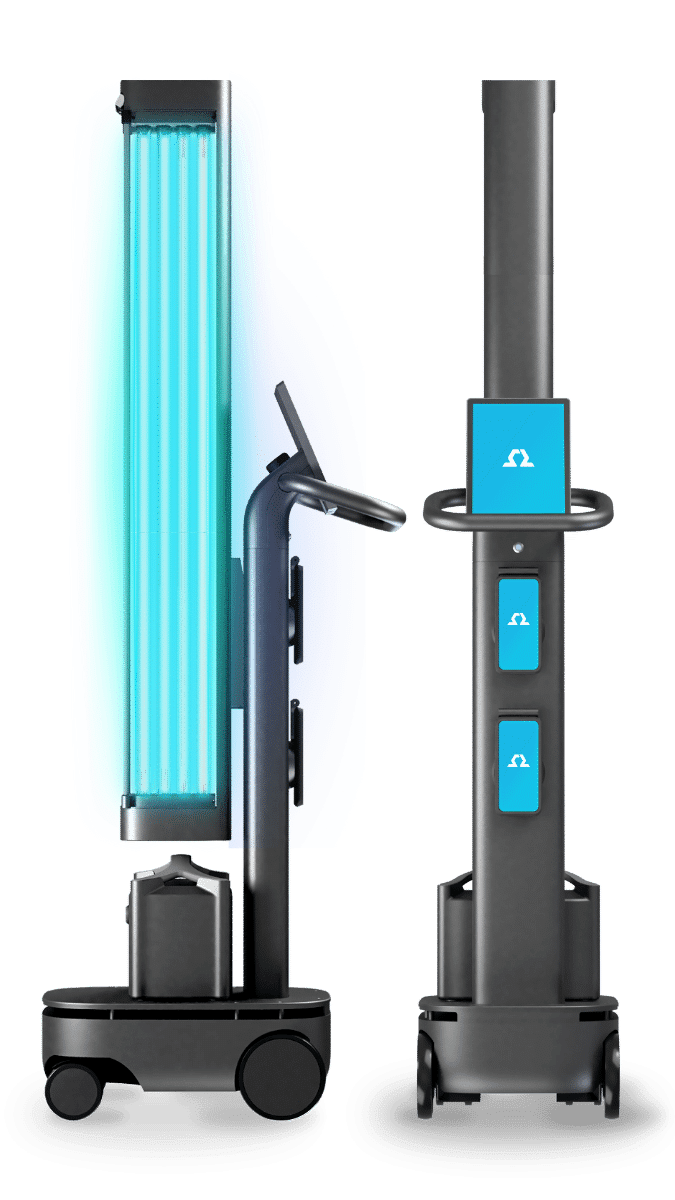

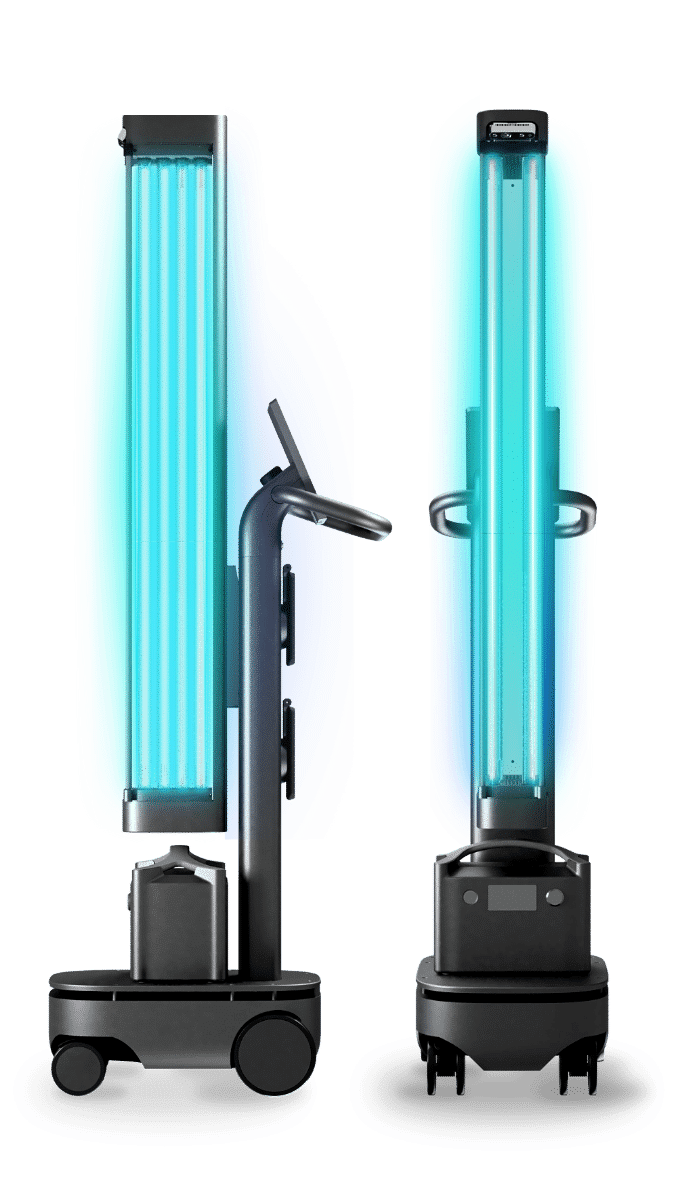

Ultimately, we’re proud to manufacture our disinfection and telepresence robots in America while still being an international company — both with our team members in Vietnam as well as selling our products worldwide. And by building in-house with our own farm of 3D printers, we can ensure that those products meet the highest standards of quality, usability, and customization for our customers.